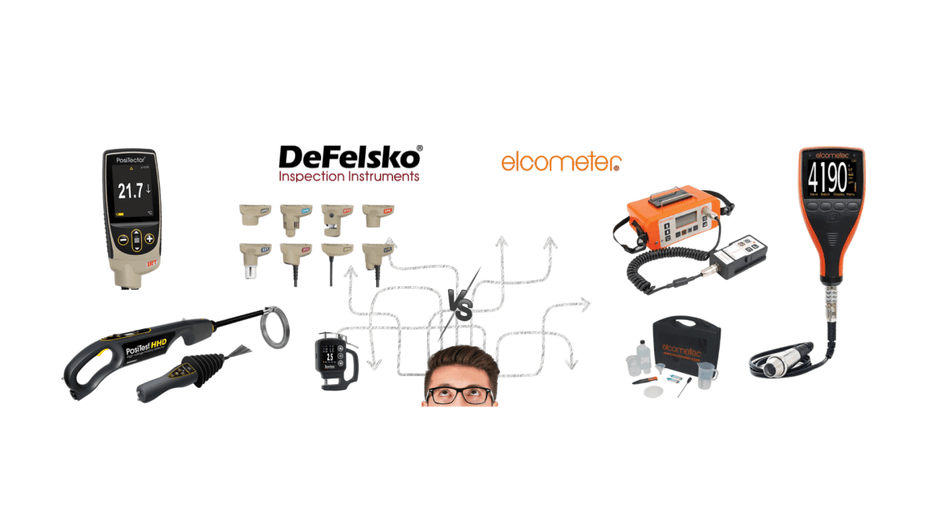

Defelsko vs Elcometer Comparison! Discover the #1 Sandblasting Inspection Solution.

This article compares DeFelsko and Elcometer's product lines across key categories—coating thickness gauges, surface profile meas...

Whatsapp: +966-53-579-9409

Couldn't load pickup availability

Engineered for Middle East Conditions: Unlike imported alternatives, SA Glass Beads are specifically processed to perform in extreme temperatures up to 50°C and coastal humidity levels exceeding 80%, ensuring consistent flow through equipment.

Compliance Guaranteed: Meets all major GCC contractor specifications including Saudi Aramco SAES-H-101, ADNOC HSE standards, and Kuwait Oil Company surface preparation requirements.

Local Stock & Support: Maintained inventory in Dammam and Jubail ensures immediate availability for shutdown projects, with technical support from certified blasting specialists.

Proven ROI: Reduces abrasive consumption by 30%, eliminates embedding rework, and cuts disposal costs - delivering typical project savings of 15-20% versus traditional abrasives.

| Property | Value |

|---|---|

| Specific Gravity | 2.5 |

| Bulk Density | 1.4 - 1.6 Ton/m³ |

| Hardness | 5.5 - 7.0 MOH |

| Particle Shape | Spherical/Rounded |

| Free Silica Content | <1% (Maximum) |

| Chloride Content | <25 ppm |

| Moisture Content | <0.1% |

| Color | Multicolor (Clear/Green/Brown) |

| Component | Percentage (%) |

|---|---|

| Silicates (SiO₂) | 70% |

| Sodium Oxide (Na₂O) | 12% |

| Calcium Oxide (CaO) | 8% |

| Aluminum Oxide (Al₂O₃) | 5% |

| Ferric Oxide (Fe₂O₃) | 5% |

| Magnesium Oxide (MgO) | 2% |

Engineered for Middle East Conditions: Unlike imported alternatives, SA Glass Beads are specifically processed to perform in extreme temperatures up to 50°C and coastal humidity levels exceeding 80%, ensuring consistent flow through equipment.

Compliance Guaranteed: Meets all major GCC contractor specifications including Saudi Aramco SAES-H-101, ADNOC HSE standards, and Kuwait Oil Company surface preparation requirements.

Local Stock & Support: Maintained inventory in Dammam and Jubail ensures immediate availability for shutdown projects, with technical support from certified blasting specialists.

Proven ROI: Reduces abrasive consumption by 30%, eliminates embedding rework, and cuts disposal costs - delivering typical project savings of 15-20% versus traditional abrasives.

| Property | Value |

|---|---|

| Specific Gravity | 2.5 |

| Bulk Density | 1.4 - 1.6 Ton/m³ |

| Hardness | 5.5 - 7.0 MOH |

| Particle Shape | Spherical/Rounded |

| Free Silica Content | <1% (Maximum) |

| Chloride Content | <25 ppm |

| Moisture Content | <0.1% |

| Color | Multicolor (Clear/Green/Brown) |

| Component | Percentage (%) |

|---|---|

| Silicates (SiO₂) | 70% |

| Sodium Oxide (Na₂O) | 12% |

| Calcium Oxide (CaO) | 8% |

| Aluminum Oxide (Al₂O₃) | 5% |

| Ferric Oxide (Fe₂O₃) | 5% |

| Magnesium Oxide (MgO) | 2% |

This article compares DeFelsko and Elcometer's product lines across key categories—coating thickness gauges, surface profile meas...

Introduction Proper surface preparation is the foundation of any successful painting or coating job. No matter how high-quality the paint or coatin...

Sandblasting is a powerful industrial cleaning method that uses high-pressure abrasive materials to prepare, clean, and finish metal surfaces. In S...