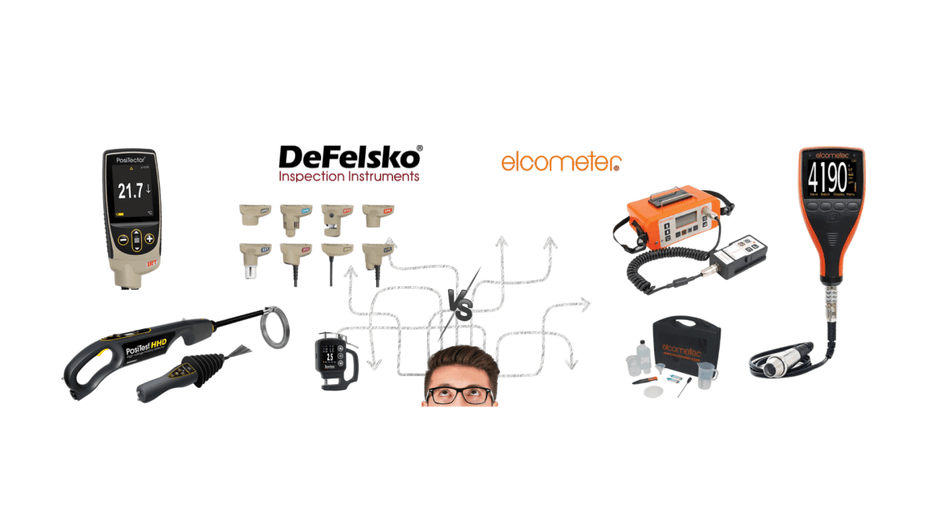

Defelsko vs Elcometer Comparison! Discover the #1 Sandblasting Inspection Solution.

This article compares DeFelsko and Elcometer's product lines across key categories—coating thickness gauges, surface profile meas...

Whatsapp: +966-53-579-9409

Couldn't load pickup availability

Built for GCC Conditions: Unlike standard air tanks, Blastline combination units are specifically engineered to handle the extreme heat, humidity, and dust conditions typical in Saudi Arabia, UAE, and Kuwait industrial sites while providing integrated cooling and moisture control.

Proven Reliability: ASME certification ensures compliance with international safety standards required by major contractors like Saudi Aramco, SABIC, and other GCC industrial giants, while the combination design reduces system complexity and failure points.

Local Support: With service centers in Dammam and availability across the Eastern Province, we provide fast delivery and technical support when you need it most.

Cost-Effective Operation: Integrated aftercooler and moisture separation reduces maintenance costs and prevents expensive downtime caused by water contamination and overheating in compressed air systems.

Built for GCC Conditions: Unlike standard air tanks, Blastline combination units are specifically engineered to handle the extreme heat, humidity, and dust conditions typical in Saudi Arabia, UAE, and Kuwait industrial sites while providing integrated cooling and moisture control.

Proven Reliability: ASME certification ensures compliance with international safety standards required by major contractors like Saudi Aramco, SABIC, and other GCC industrial giants, while the combination design reduces system complexity and failure points.

Local Support: With service centers in Dammam and availability across the Eastern Province, we provide fast delivery and technical support when you need it most.

Cost-Effective Operation: Integrated aftercooler and moisture separation reduces maintenance costs and prevents expensive downtime caused by water contamination and overheating in compressed air systems.

This article compares DeFelsko and Elcometer's product lines across key categories—coating thickness gauges, surface profile meas...

Introduction Proper surface preparation is the foundation of any successful painting or coating job. No matter how high-quality the paint or coatin...

Sandblasting is a powerful industrial cleaning method that uses high-pressure abrasive materials to prepare, clean, and finish metal surfaces. In S...