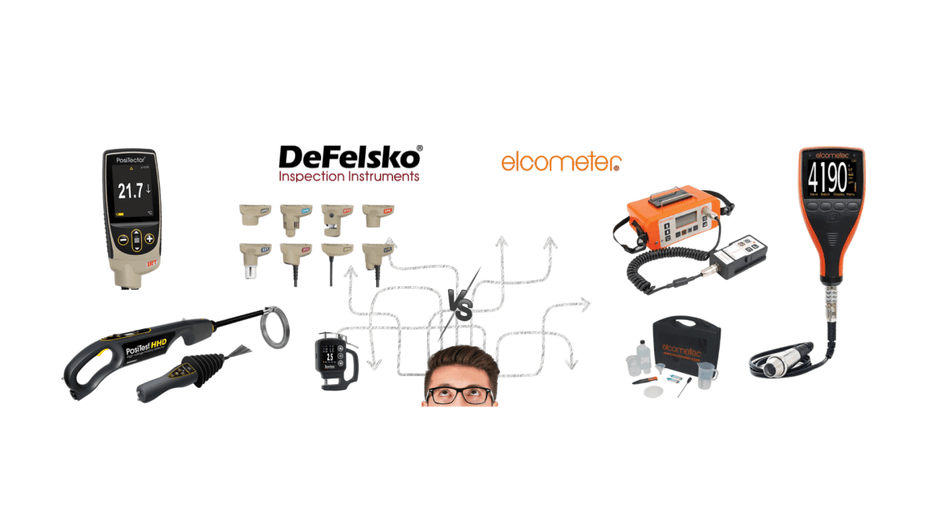

Defelsko vs Elcometer Comparison! Discover the #1 Sandblasting Inspection Solution.

This article compares DeFelsko and Elcometer's product lines across key categories—coating thickness gauges, surface profile meas...

Whatsapp: +966-53-579-9409

Couldn't load pickup availability

Silicon Carbide nozzles offer exceptional durability and performance for precision blasting applications. Lightweight and engineered with advanced materials, these nozzles provide improved wear resistance compared to traditional tungsten carbide options. The soft nylon outer jacket absorbs shocks, protecting the nozzle from cracking and enhancing overall longevity.

| Diameter | Typical Applications | Differences |

|---|---|---|

| 5 mm | Precision cleaning, small parts, delicate surfaces | Lowest air consumption, most precise blast pattern |

| 6 mm | General industrial cleaning, medium-scale projects | Balanced between precision and coverage |

| 7 mm | Large surface preparation, heavy-duty cleaning | Highest air consumption, widest blast pattern |

Silicon Carbide nozzles offer exceptional durability and performance for precision blasting applications. Lightweight and engineered with advanced materials, these nozzles provide improved wear resistance compared to traditional tungsten carbide options. The soft nylon outer jacket absorbs shocks, protecting the nozzle from cracking and enhancing overall longevity.

| Diameter | Typical Applications | Differences |

|---|---|---|

| 5 mm | Precision cleaning, small parts, delicate surfaces | Lowest air consumption, most precise blast pattern |

| 6 mm | General industrial cleaning, medium-scale projects | Balanced between precision and coverage |

| 7 mm | Large surface preparation, heavy-duty cleaning | Highest air consumption, widest blast pattern |

This article compares DeFelsko and Elcometer's product lines across key categories—coating thickness gauges, surface profile meas...

Introduction Proper surface preparation is the foundation of any successful painting or coating job. No matter how high-quality the paint or coatin...

Sandblasting is a powerful industrial cleaning method that uses high-pressure abrasive materials to prepare, clean, and finish metal surfaces. In S...