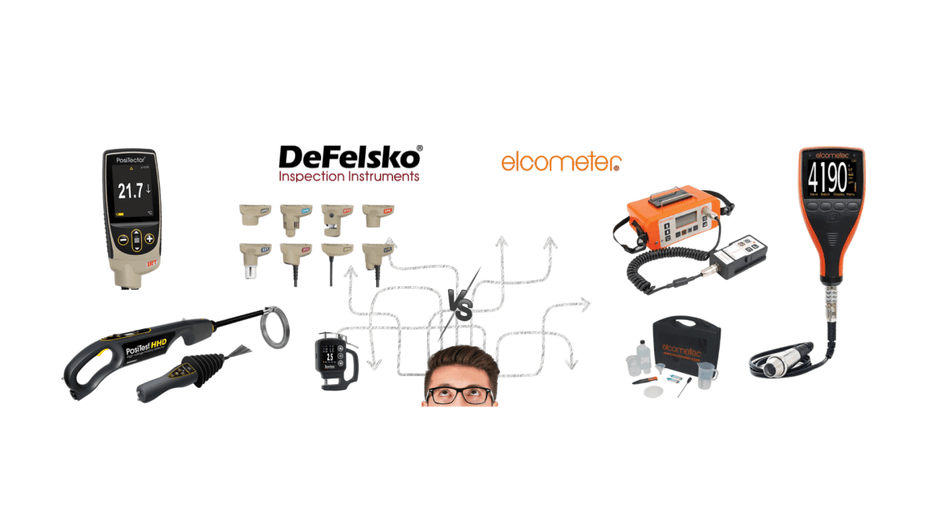

Defelsko vs Elcometer Comparison! Discover the #1 Sandblasting Inspection Solution.

This article compares DeFelsko and Elcometer's product lines across key categories—coating thickness gauges, surface profile meas...

Couldn't load pickup availability

Deccan Garnet is an environmentally friendly, hard, angular abrasive. This premium natural mineral provides exceptional performance for a wide variety of abrasive blasting applications including blast rooms, shipyards, tanks, offshore platforms, and pipelines.

Because it is a hard and heavy abrasive with a hardness of 7.5-8.0 Mohs, Deccan Garnet increases productivity while reducing the amount of abrasive needed. The heavy sub-angular shaped grains provide high impact and cutting action with low amounts of dust emitted. With less dust and improved cutting ability, garnet can reduce cleanup time and increase productivity.

Abundant raw material reserves in the Deccan Peninsula and a quality-controlled processing plant ensures consistent product availability of high quality. Deccan Garnet can be recycled several times, cutting fast and reducing abrasive consumption. Less abrasive used means lower disposal cost.

| Mineral | Content (%) |

|---|---|

| Garnet | 97.3 – 98.9 |

| -Purity (Min.) | 97.0 |

| Ilmenite | 1.0 – 2.5 |

| Quartz | 0.1 – 0.3 |

| Non-magnetic (other than quartz) | 0.4 – 0.7 |

| Zircon | 0.2 |

| Monazite | 0.21 |

| Leucoxene | 0.10 |

| Rutile | 0.1 |

| Sillimanite + Kyanite | Trace |

| Compound | Content (%) |

|---|---|

| SiO₂ | 40.0 |

| Al₂O₃ + ZrO₂ | 21.0 |

| Al₂O₂ (assumed Al₂O₃) | 21.0 |

| FeO | 26.0 |

| MgO | 6.8 |

| Fe₂O₃ | 2.9 |

| TiO₂ | 1.0 |

| CaO | 0.9 |

| MnO | 0.5 |

| ZrO₂ | 0.01 |

| P₂O₅ | 0.03 |

| Cr₂O₃ | 0.04 |

| Mesh (ASTM) | Sieve Opening (µm) | Cumulative Weight% Retained |

|---|---|---|

| 35 | 425 | 0.0 – 5.0 |

| 48 | 300 | 10.0 – 30.0 |

| 65 | 212 | 74.0 – 90.0 |

| 100 | 150 | 94.0 – 99.0 |

| 150 | 106 | 99.5 – 100 |

Deccan Garnet is an environmentally friendly, hard, angular abrasive. This premium natural mineral provides exceptional performance for a wide variety of abrasive blasting applications including blast rooms, shipyards, tanks, offshore platforms, and pipelines.

Because it is a hard and heavy abrasive with a hardness of 7.5-8.0 Mohs, Deccan Garnet increases productivity while reducing the amount of abrasive needed. The heavy sub-angular shaped grains provide high impact and cutting action with low amounts of dust emitted. With less dust and improved cutting ability, garnet can reduce cleanup time and increase productivity.

Abundant raw material reserves in the Deccan Peninsula and a quality-controlled processing plant ensures consistent product availability of high quality. Deccan Garnet can be recycled several times, cutting fast and reducing abrasive consumption. Less abrasive used means lower disposal cost.

| Mineral | Content (%) |

|---|---|

| Garnet | 97.3 – 98.9 |

| -Purity (Min.) | 97.0 |

| Ilmenite | 1.0 – 2.5 |

| Quartz | 0.1 – 0.3 |

| Non-magnetic (other than quartz) | 0.4 – 0.7 |

| Zircon | 0.2 |

| Monazite | 0.21 |

| Leucoxene | 0.10 |

| Rutile | 0.1 |

| Sillimanite + Kyanite | Trace |

| Compound | Content (%) |

|---|---|

| SiO₂ | 40.0 |

| Al₂O₃ + ZrO₂ | 21.0 |

| Al₂O₂ (assumed Al₂O₃) | 21.0 |

| FeO | 26.0 |

| MgO | 6.8 |

| Fe₂O₃ | 2.9 |

| TiO₂ | 1.0 |

| CaO | 0.9 |

| MnO | 0.5 |

| ZrO₂ | 0.01 |

| P₂O₅ | 0.03 |

| Cr₂O₃ | 0.04 |

| Mesh (ASTM) | Sieve Opening (µm) | Cumulative Weight% Retained |

|---|---|---|

| 35 | 425 | 0.0 – 5.0 |

| 48 | 300 | 10.0 – 30.0 |

| 65 | 212 | 74.0 – 90.0 |

| 100 | 150 | 94.0 – 99.0 |

| 150 | 106 | 99.5 – 100 |

This article compares DeFelsko and Elcometer's product lines across key categories—coating thickness gauges, surface profile meas...

Introduction Proper surface preparation is the foundation of any successful painting or coating job. No matter how high-quality the paint or coatin...

The Power of Abrasives: A Comprehensive Guide to Sandblasting and its Applications Abrasive blasting is a versatile method used to modify a surf...