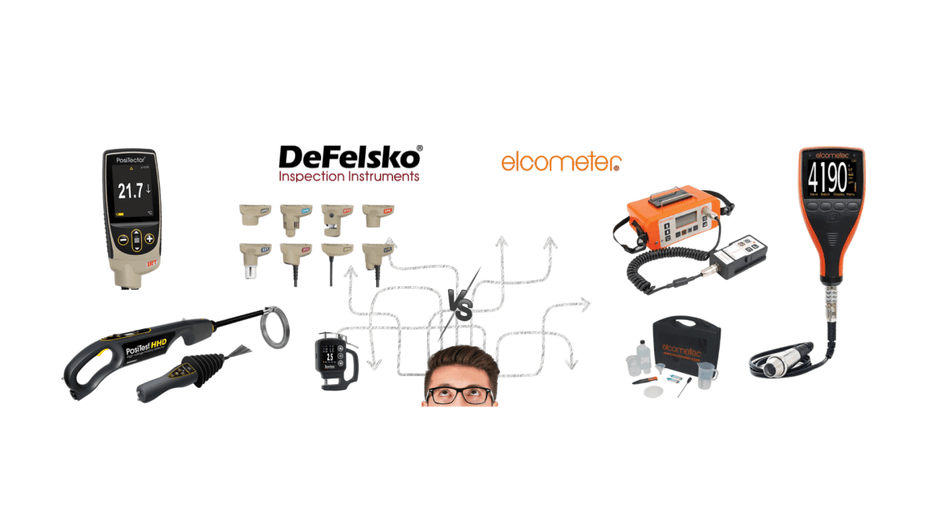

Defelsko vs Elcometer Comparison! Discover the #1 Sandblasting Inspection Solution.

This article compares DeFelsko and Elcometer's product lines across key categories—coating thickness gauges, surface profile meas...

Couldn't load pickup availability

The RMS is used to control the supply of compressed air to the blast pot and blast hose. The pneumatic remote control system consists of a inlet valve, and outlet valve, a dead man handle and a ‘twinline’ hose. Upon receiving air supply from the engaged deadman han- dle the inlet valve instantaneously opens, outlet valve clos- es, the machine gets pressurized and blasting operation begins. Release of the deadman handle reverses this pro- cedure to depressurize the machine allowing the pop-up valve filling port to open. Reserve supply of abrasive in the concave head or storage hopper then refills the machine.

The instant start/stop of a remote control blast machine will effect 20-40% abrasive saving, 50% labour reduction, ensure maximum site safety and an overall increase in rate of production.

The RMS is used to control the supply of compressed air to the blast pot and blast hose. The pneumatic remote control system consists of a inlet valve, and outlet valve, a dead man handle and a ‘twinline’ hose. Upon receiving air supply from the engaged deadman han- dle the inlet valve instantaneously opens, outlet valve clos- es, the machine gets pressurized and blasting operation begins. Release of the deadman handle reverses this pro- cedure to depressurize the machine allowing the pop-up valve filling port to open. Reserve supply of abrasive in the concave head or storage hopper then refills the machine.

The instant start/stop of a remote control blast machine will effect 20-40% abrasive saving, 50% labour reduction, ensure maximum site safety and an overall increase in rate of production.

This article compares DeFelsko and Elcometer's product lines across key categories—coating thickness gauges, surface profile meas...

Introduction Proper surface preparation is the foundation of any successful painting or coating job. No matter how high-quality the paint or coatin...

The Power of Abrasives: A Comprehensive Guide to Sandblasting and its Applications Abrasive blasting is a versatile method used to modify a surf...