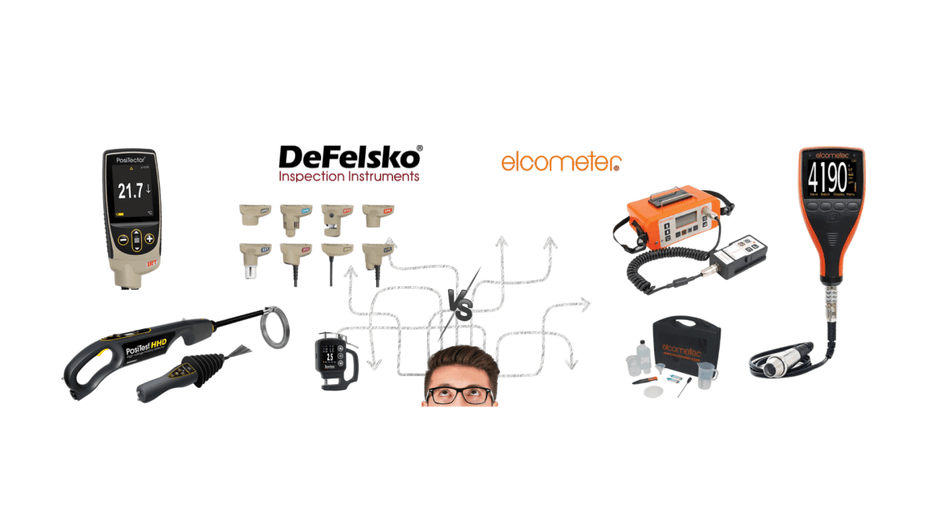

Defelsko vs Elcometer Comparison! Discover the #1 Sandblasting Inspection Solution.

This article compares DeFelsko and Elcometer's product lines across key categories—coating thickness gauges, surface profile meas...

Couldn't load pickup availability

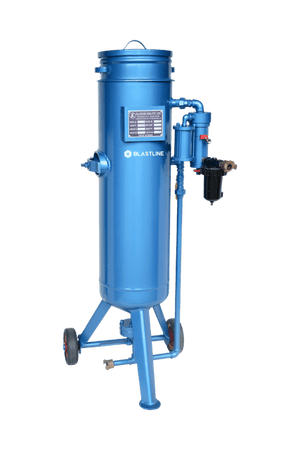

Blastline offer a range of portable blasting machines able to cope with virtually all types of blasting environment. Whether on site, where the need is for maneuverability, or in a fixed environment such as a blast room. Tried and tested throughout the world the Blastline range of blast machines combines rugged efficient operation with maximum site safety.

Hydraulically tested to twice the working pressure and comes with a test certificate and a comprehensive machine manual.

A choice of automatic or manually operated machines are available along with a grit valve or flat sand valve.

All items are subject to availability of stock

* Above configurations are only for 200 Ltr & 300 Ltr Blast Pots.

| Model | Capacity (Liter) | Height (mm) | Diameter (mm) | Description |

|---|---|---|---|---|

| BL1080 | 20 | 711 | 254 | Smallest in our range, ideal for remedial work, glass etching, and general maintenance. Easily transported with a blast time of approx. 10-15 mins. |

| BL14160 | 50 | 1061 | 357 | With a continuous blast time of 20-25 minutes, this machine is ideal for small to medium contracts where mobility yet high production is required. |

| BL20300 | 100 | 1061 | 508 | Designed for the medium contractor, with a continuous blast time of 35-40 minutes. |

| BL24650 | 200 | 1346 | 610 | A robust machine for professional contractors, offering a continuous blast time of 45-50 minutes. Ideal for shipyards, refineries, gas, and heavy fabrication industries. |

| BL24800 | 300 | 1575 | 610 | The largest machine in our standard range, designed for maximum output and minimum downtime between refills while still being portable. |

Blastline offer a range of portable blasting machines able to cope with virtually all types of blasting environment. Whether on site, where the need is for maneuverability, or in a fixed environment such as a blast room. Tried and tested throughout the world the Blastline range of blast machines combines rugged efficient operation with maximum site safety.

Hydraulically tested to twice the working pressure and comes with a test certificate and a comprehensive machine manual.

A choice of automatic or manually operated machines are available along with a grit valve or flat sand valve.

All items are subject to availability of stock

* Above configurations are only for 200 Ltr & 300 Ltr Blast Pots.

| Model | Capacity (Liter) | Height (mm) | Diameter (mm) | Description |

|---|---|---|---|---|

| BL1080 | 20 | 711 | 254 | Smallest in our range, ideal for remedial work, glass etching, and general maintenance. Easily transported with a blast time of approx. 10-15 mins. |

| BL14160 | 50 | 1061 | 357 | With a continuous blast time of 20-25 minutes, this machine is ideal for small to medium contracts where mobility yet high production is required. |

| BL20300 | 100 | 1061 | 508 | Designed for the medium contractor, with a continuous blast time of 35-40 minutes. |

| BL24650 | 200 | 1346 | 610 | A robust machine for professional contractors, offering a continuous blast time of 45-50 minutes. Ideal for shipyards, refineries, gas, and heavy fabrication industries. |

| BL24800 | 300 | 1575 | 610 | The largest machine in our standard range, designed for maximum output and minimum downtime between refills while still being portable. |

This article compares DeFelsko and Elcometer's product lines across key categories—coating thickness gauges, surface profile meas...

Introduction Proper surface preparation is the foundation of any successful painting or coating job. No matter how high-quality the paint or coatin...

The Power of Abrasives: A Comprehensive Guide to Sandblasting and its Applications Abrasive blasting is a versatile method used to modify a surf...